Klemke Trial Testimony – Part 2 of 2

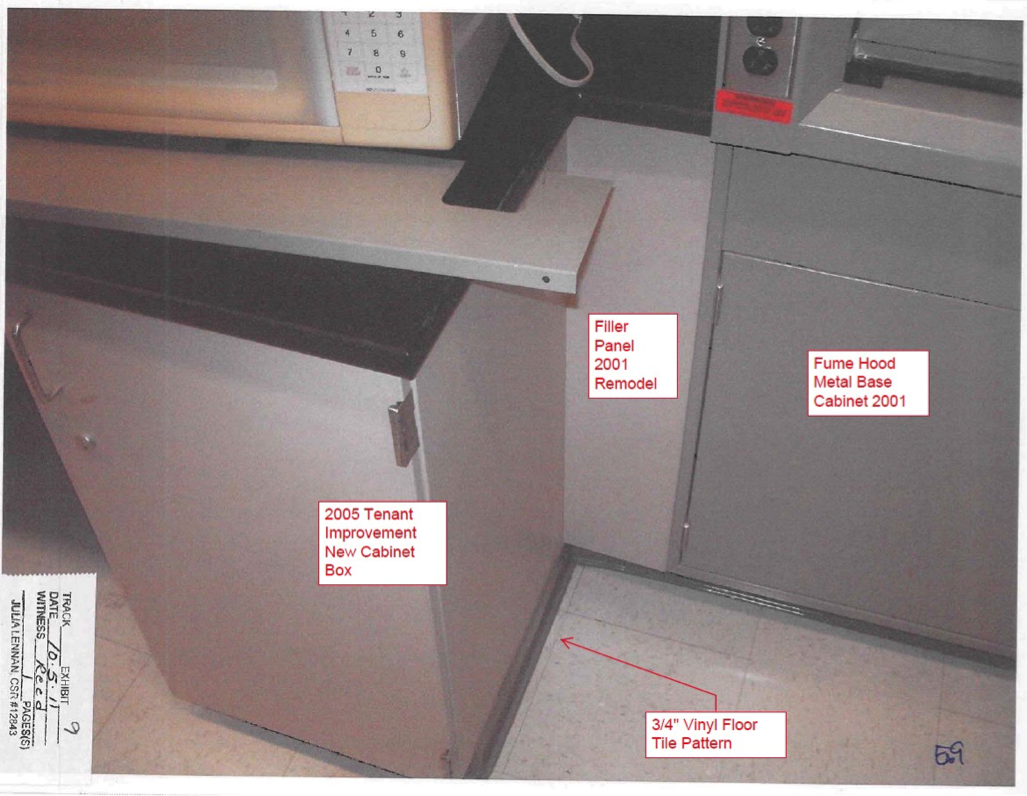

The second location where the plaintiffs’ team alleged the acid waste pipes had been left uncapped as a result of the 2005 tenant improvement work contracted by our client was behind a fume hood appliance. The fume hood appliance is a unique devise. This one had been upgraded from a lesser model during the 2001 remodel project. The 2001 activities did not include any of the same companies/subcontractors as the 2005 tenant improvement work and not part of this court case. This device allows lab technicians to work with noxious gas chemicals through clear acrylic or glass walled sides and attached rubber gloved sleeves. The appliance is connected to elaborate fume ventilation filtration flue system. It also has fresh water (hot and cold), air and a lab sink drain system. This drain piping outlet is of course connected to the subject acid waste glass pipes. The fume hood appliance has a steel base cabinet box. Within the base box stand you can see the supply and waste plumbing connected to the hooded basin work area. There are three hinged cabinet doors at the front of the cabinet box and an approximately 9” x 9” access panel at the rear. The access panel is secured by screws accessible from the interior of the appliance base cabinet. The lab folks store some of the more sensitive chemicals within one box that is bright yellow with many danger notification stickers and signs affixed to the appliance.

The second location where the plaintiffs’ team alleged the acid waste pipes had been left uncapped as a result of the 2005 tenant improvement work contracted by our client was behind a fume hood appliance. The fume hood appliance is a unique devise. This one had been upgraded from a lesser model during the 2001 remodel project. The 2001 activities did not include any of the same companies/subcontractors as the 2005 tenant improvement work and not part of this court case. This device allows lab technicians to work with noxious gas chemicals through clear acrylic or glass walled sides and attached rubber gloved sleeves. The appliance is connected to elaborate fume ventilation filtration flue system. It also has fresh water (hot and cold), air and a lab sink drain system. This drain piping outlet is of course connected to the subject acid waste glass pipes. The fume hood appliance has a steel base cabinet box. Within the base box stand you can see the supply and waste plumbing connected to the hooded basin work area. There are three hinged cabinet doors at the front of the cabinet box and an approximately 9” x 9” access panel at the rear. The access panel is secured by screws accessible from the interior of the appliance base cabinet. The lab folks store some of the more sensitive chemicals within one box that is bright yellow with many danger notification stickers and signs affixed to the appliance.

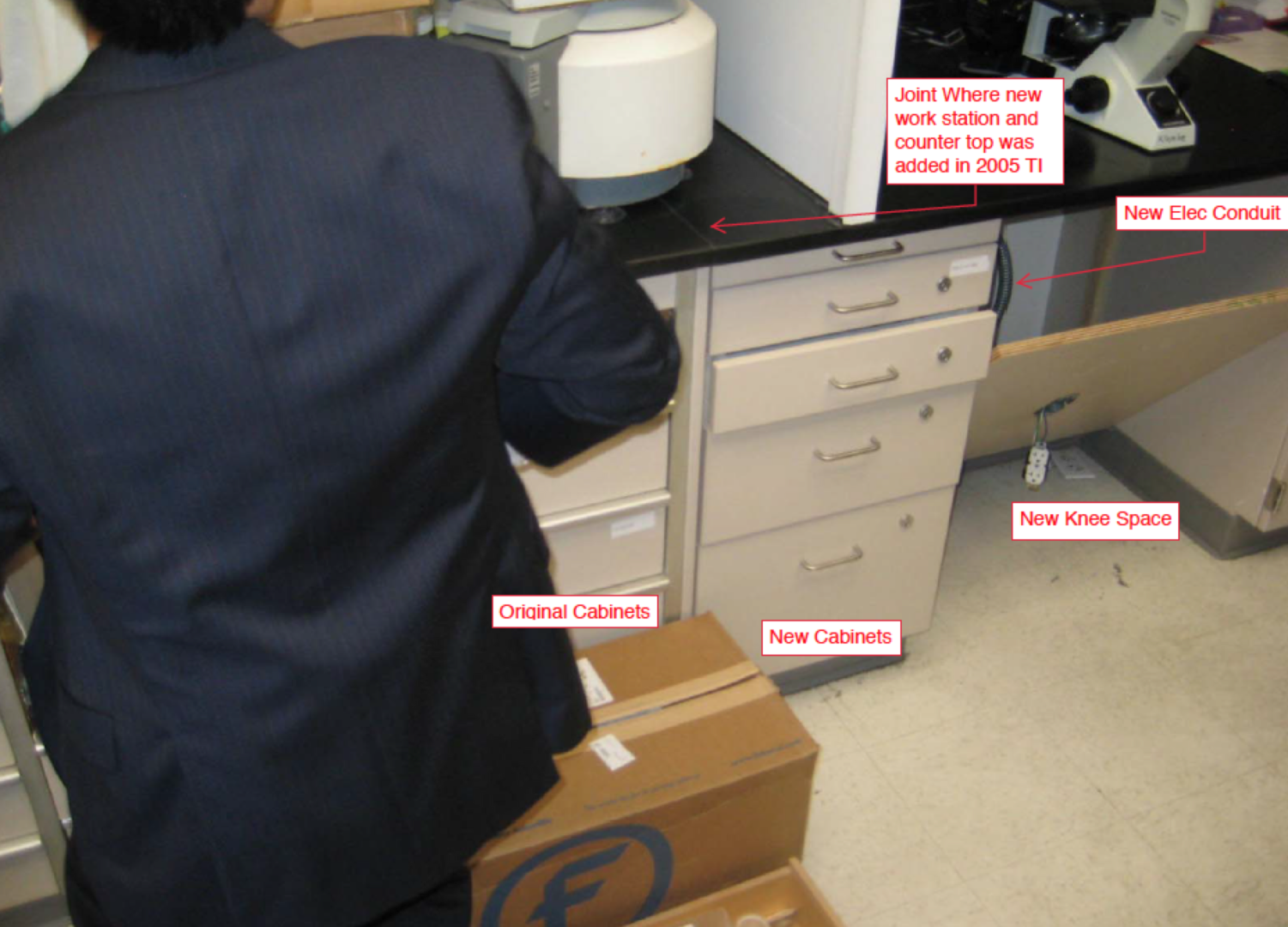

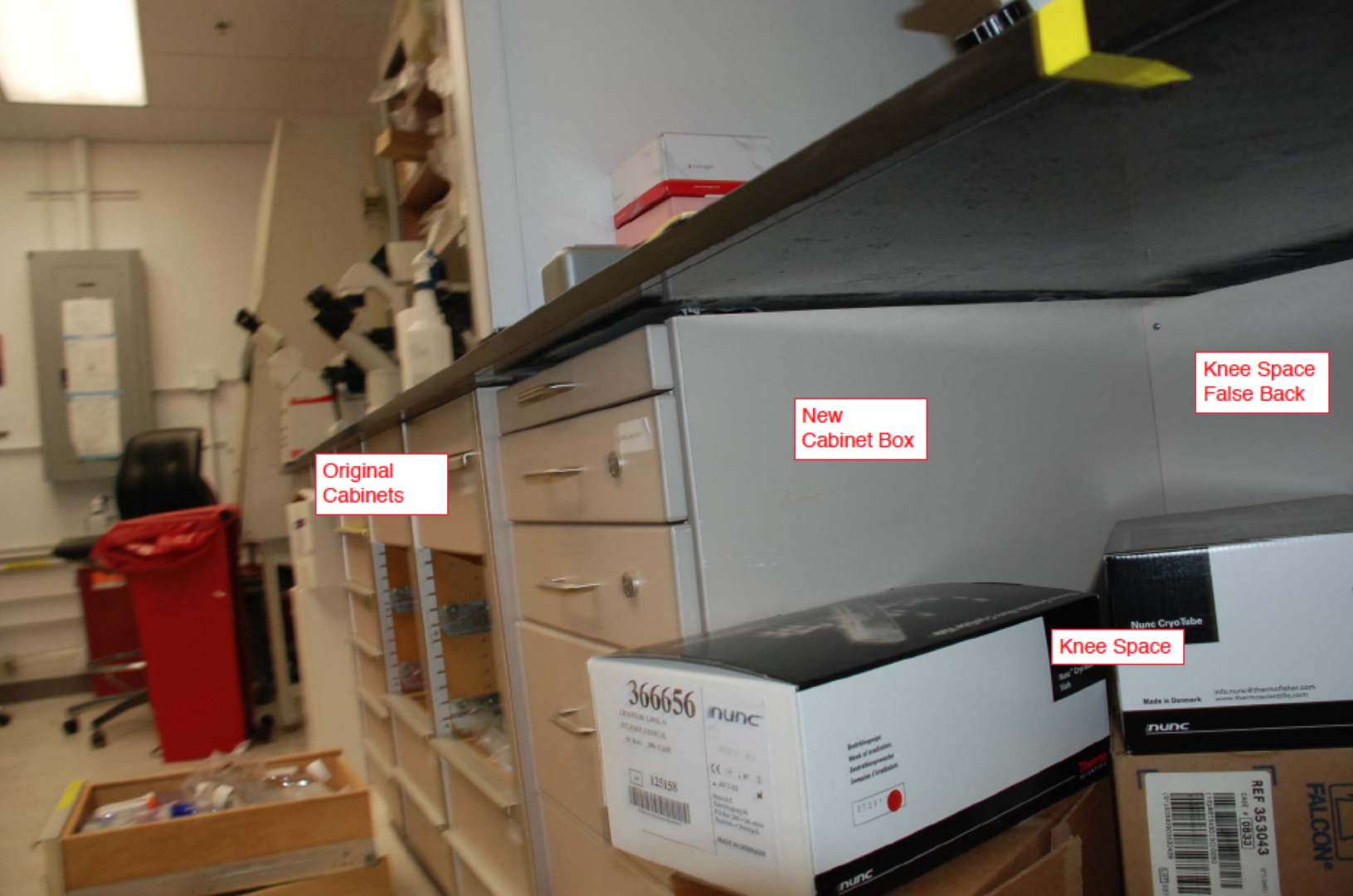

This location overview is at the rear left of the lab room 1037. This is a long, thin laboratory with desk tops and working countertops on both sides of the room with approximately a 5’ walking path down the middle. The upper areas above the working surfaces on the left and right are filled with shelves that stack as high as workers can reach. The countertops have sinks with hot and cold fresh water and gas outlets. The sinks and drains are all connected in some way to the subject acid waste pipes.

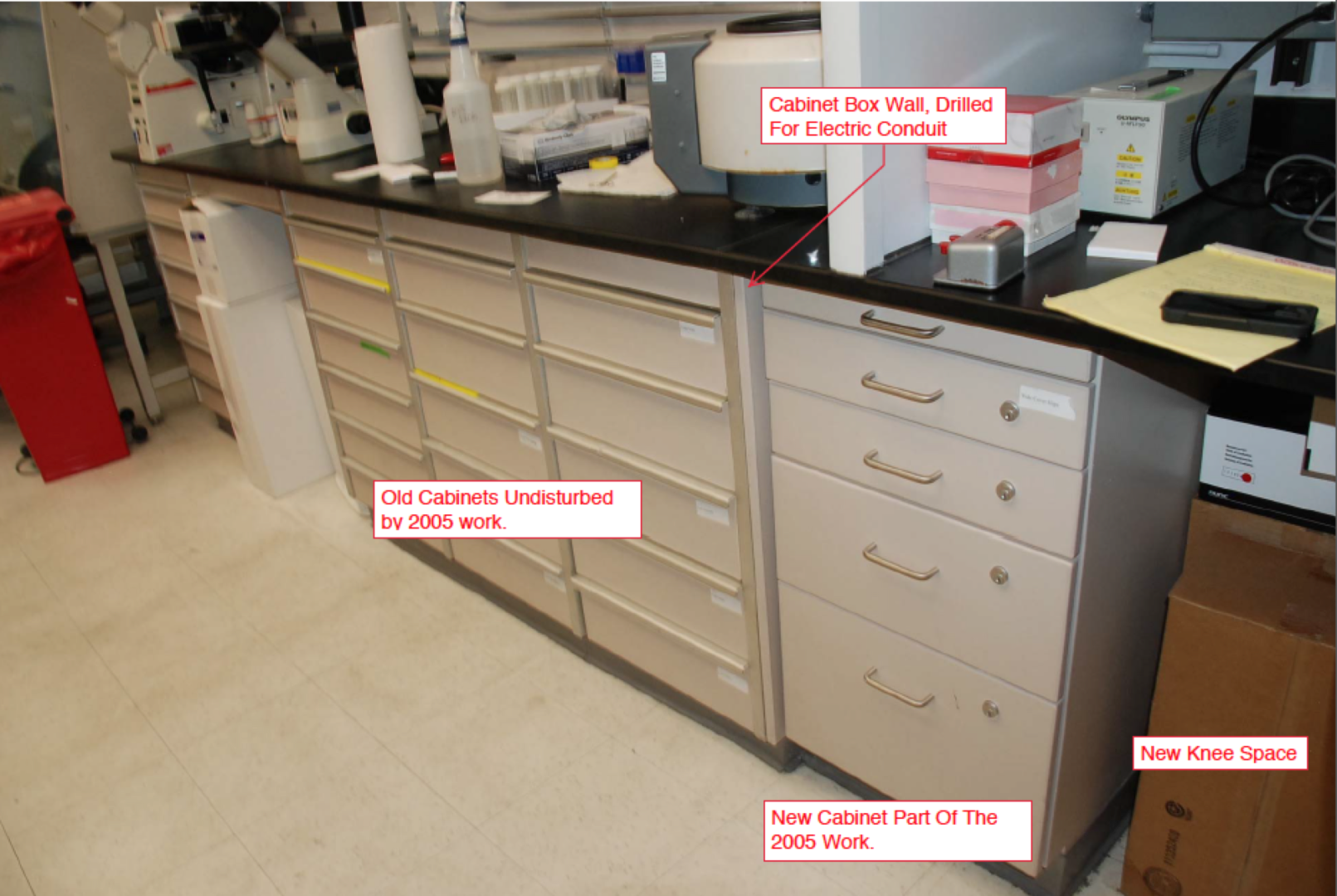

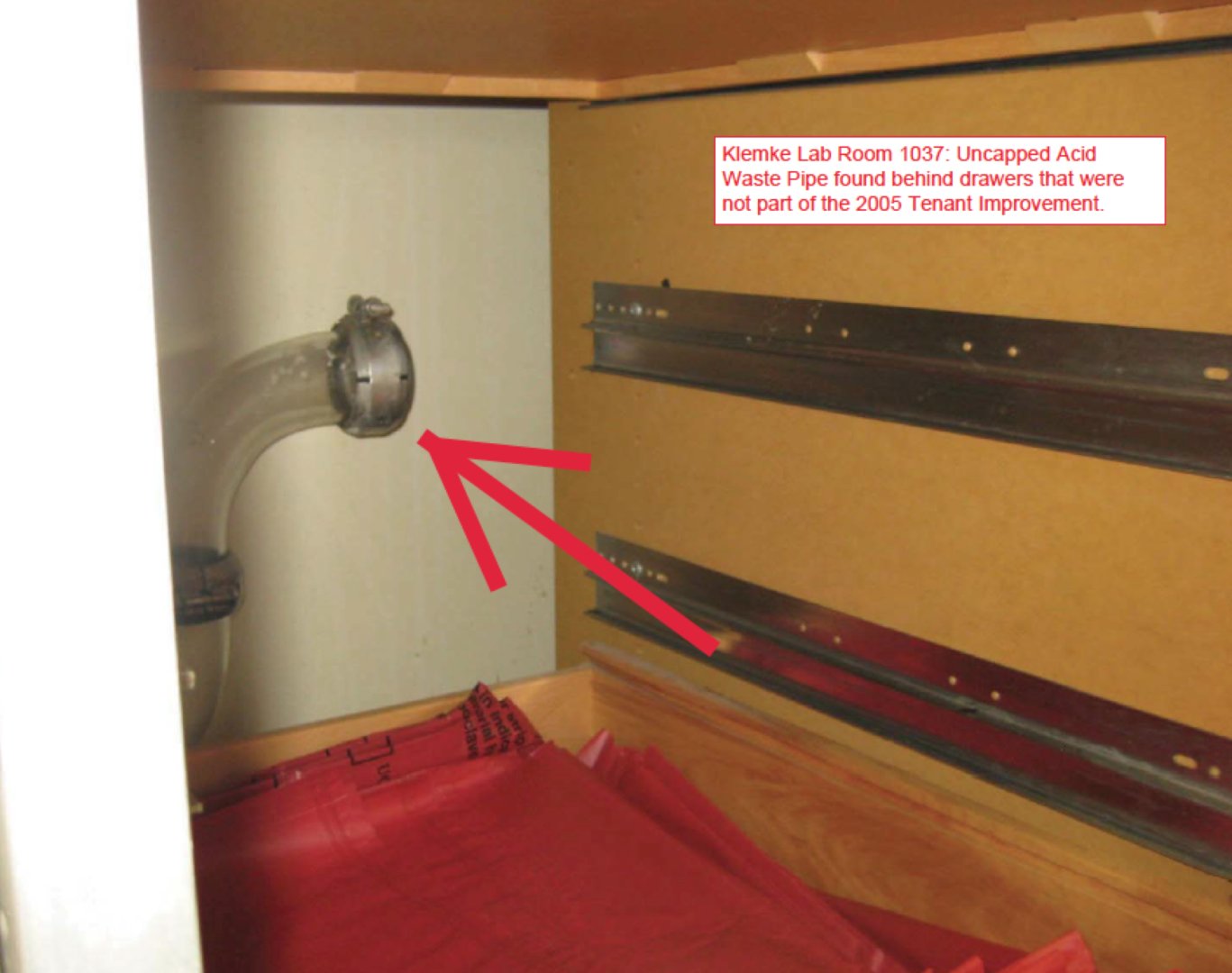

This configuration was a bit more difficult to explain how an uncapped acid waste pipe was left exposed and visible to the naked eye in that the construction and demolition work and new case work (cabinet and shelves) were very close in proximity to the uncapped pipe. The previously discussed missing pipe was 4’ away from the new case work and behind two undisturbed drawer banks. This uncapped pipe end was within 1’ of the new cabinets, countertops and shelving. Not to mention a wall that used to run the full left side of this lab, it was being demoed and cut back to within the same 1’ of the uncapped pipe end.

This configuration was a bit more difficult to explain how an uncapped acid waste pipe was left exposed and visible to the naked eye in that the construction and demolition work and new case work (cabinet and shelves) were very close in proximity to the uncapped pipe. The previously discussed missing pipe was 4’ away from the new case work and behind two undisturbed drawer banks. This uncapped pipe end was within 1’ of the new cabinets, countertops and shelving. Not to mention a wall that used to run the full left side of this lab, it was being demoed and cut back to within the same 1’ of the uncapped pipe end.

The premise of the plaintiffs’ team was pitched as the plumber left the pipe uncapped. The case work contractor installed new countertops and cabinet boxes concealing the uncapped pipe end and the general contractor oversaw the entire thing and did nothing about it and did not catch it.

No destructive testing was performed. The investigation that TVCI performed at the lab was the same as all other experts on the site on that day in March 2011.

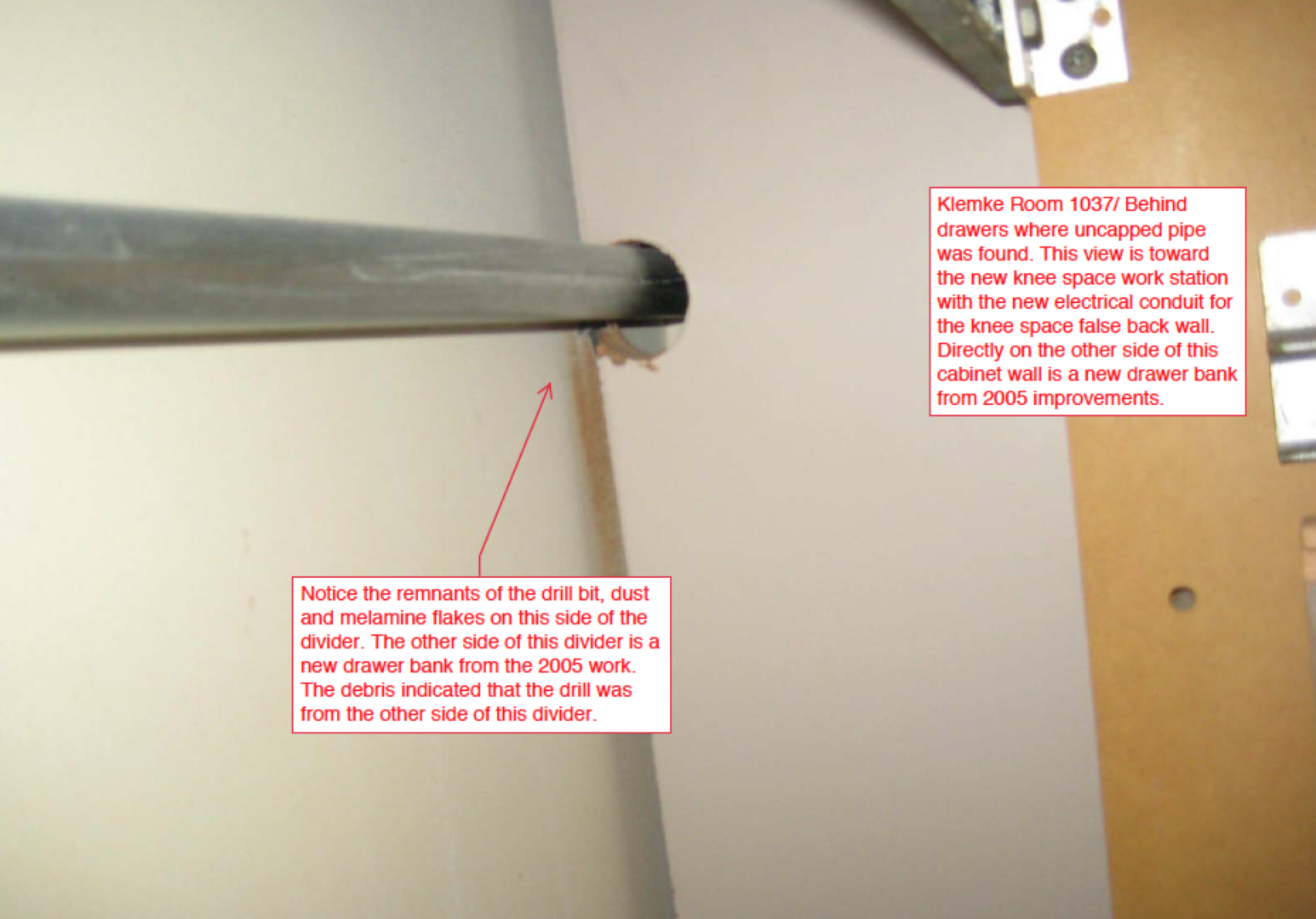

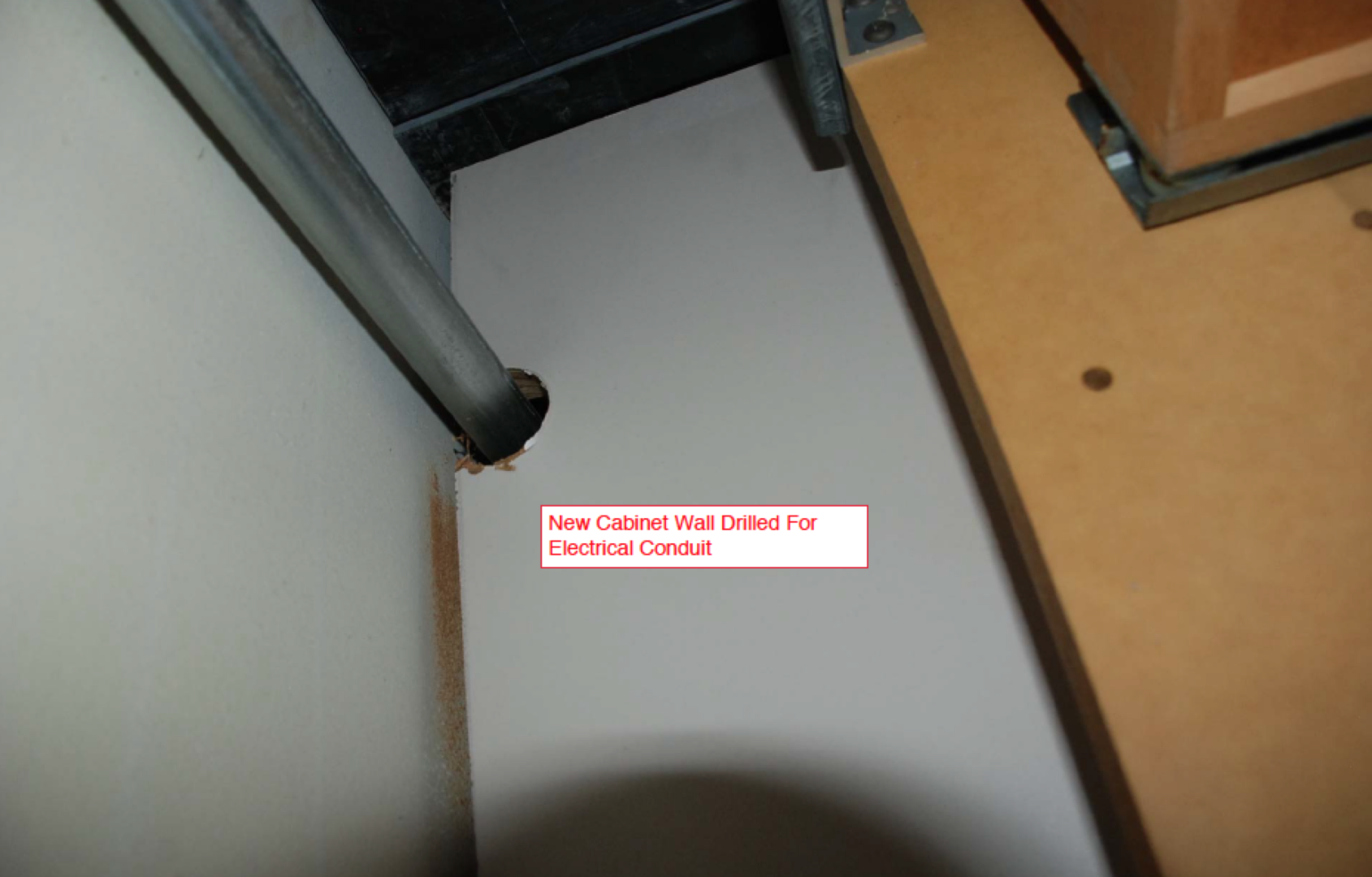

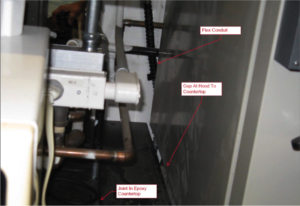

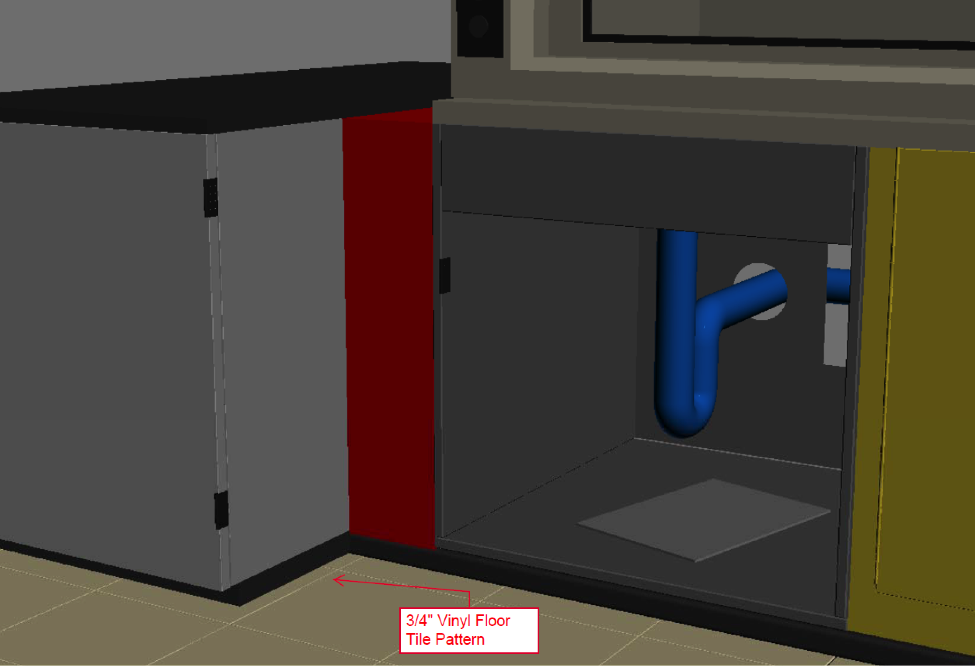

The proximity of the vinyl floor tile, its shape and dimension would become relevant at a later date, but not immediately. Originally, all experts in the case were viewing this uncapped pipe as if the cabinets were completely removed, including everything left of the fume hood appliance. They also assumed the wall that was used to separate the labs was also exposed and cut back and patched just left of the fume hood as well. One of the initial things that bothered me was there was some 3/8” flex conduit secured to the cabinet panel from the fume hood side of the cabinet ends. This could only be done if the fume hood was not in place, further the fume hood is plumbed and ducted in place and was in this position since the 2001 remodel. The second thing that did not make any sense was the amount of debris behind the fume hood, it was as if no one had been behind that cabinet for several years.

The proximity of the vinyl floor tile, its shape and dimension would become relevant at a later date, but not immediately. Originally, all experts in the case were viewing this uncapped pipe as if the cabinets were completely removed, including everything left of the fume hood appliance. They also assumed the wall that was used to separate the labs was also exposed and cut back and patched just left of the fume hood as well. One of the initial things that bothered me was there was some 3/8” flex conduit secured to the cabinet panel from the fume hood side of the cabinet ends. This could only be done if the fume hood was not in place, further the fume hood is plumbed and ducted in place and was in this position since the 2001 remodel. The second thing that did not make any sense was the amount of debris behind the fume hood, it was as if no one had been behind that cabinet for several years.

We shot the photos, took notes and did not form any hypothesis until things started moving along with the case. As we progressed toward trial, depositions were being taken of the many plaintiffs’ experts. My opposition was a well-known general contractor, one quite familiar with being on the plaintiffs’ side of cases. His deposition laid out quite well his view of how the uncapped pipes came to be, the previous location discussed, we believed was a farfetched explanation. That was the opinion (in part 1) where he felt someone took the 3’ or 4’ piece off the end and never capped it. The interesting thing is that the plans (2005) are very specific as to what is being added, including plumbing lines and what is being taken out. None of the information on the plans supported the plaintiffs’ position. There was only cabinet work at the left of the fume hood and the wall was being demolished, as well as being capped with finished drywall, eventually finish paint applied on the end.

We reviewed the testimony of the on-site inspectors for the University. We also reviewed the most knowledgeable persons from all of the subcontractors, persons on site at the time the work was being conducted. All of the information we were provided gave a pretty clear picture of how things went down on the site, contracts, change orders, as built plans, testimony, there was no specific information that illustrated or suggested that the Tennant Improvement General Contractor, had any knowledge or had to have observed the uncapped ends. We thought maybe there was more culpability for the plumber, or the cabinet guys, because they were the trades doing work in those locations, closest to the uncapped ends. The angle that was pitched by most through the deposition process was that the general contractor has ultimate control over the job, and if plumbing acid waste pipes were left uncapped and folks were injured or damaged the GC has at minimum some responsibility for overseeing and coordinating the subcontractors. I can’t say that I did not share that view early on in the case investigation.

In the job files of the project, there were change orders for extras when an uncapped pipe was found during the 2005 TI work. This establishes first that they had encountered uncapped pipes behind cabinets and appliances during their time on site through this era of construction improvements. So somehow during the 2001 major remodel or prior, there were some pipes inadvertently left uncapped. Secondly it shows that the plumber got paid extras for capping the pipes. This means there is nothing gained by hiding or missing an uncapped pipe. The company makes more for the extras, there is no reason why a plumber would encounter an exposed uncapped pipe end and just ignore it, or try to hide it.

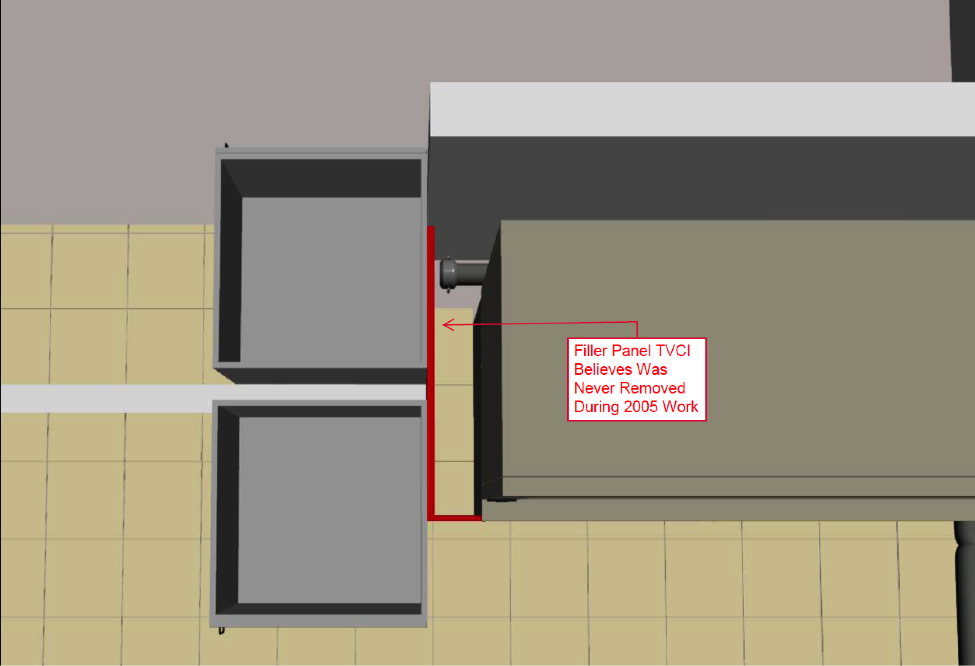

As I prepared for my deposition, I began to look at the photos a little differently. I went over my own photos all over again, anyone who had deposited their photos, I went through, a few more subtle observations started to come to light. There was a joint at the epoxy countertop about 6” to 8” from the fume hood. There was a small gap between that small section of countertop and the fume hood appliance. This explains why there is so much debris behind the fume hood, anything that fell between the countertop and appliance box was ending up behind the fume hood cabinet. You could also see from above the previously mentioned 3/8” flex conduit, where it ran and where it terminated above the counter surface. From the front, I recognized that the cabinet face between the fume hood cabinet box and the next working drawer bank cabinet box was just a filler panel. A dummy face that did not pivot, hinge or move at all, it was a blank piece of laminated cabinet face that matched the original finish and color. The joint in the countertop aligned perfectly with the joint between the lower new working cabinet box (left) and the filler panel (right). The plans show this is an existing piece of cabinet (the filler) and was not supposed to be disturbed in the 2005 improvements. The cabinet contractor was not doing anything right of that joint, neither was the plumbing contractor, nothing contracted right of the joint in the countertop.

As I prepared for my deposition, I began to look at the photos a little differently. I went over my own photos all over again, anyone who had deposited their photos, I went through, a few more subtle observations started to come to light. There was a joint at the epoxy countertop about 6” to 8” from the fume hood. There was a small gap between that small section of countertop and the fume hood appliance. This explains why there is so much debris behind the fume hood, anything that fell between the countertop and appliance box was ending up behind the fume hood cabinet. You could also see from above the previously mentioned 3/8” flex conduit, where it ran and where it terminated above the counter surface. From the front, I recognized that the cabinet face between the fume hood cabinet box and the next working drawer bank cabinet box was just a filler panel. A dummy face that did not pivot, hinge or move at all, it was a blank piece of laminated cabinet face that matched the original finish and color. The joint in the countertop aligned perfectly with the joint between the lower new working cabinet box (left) and the filler panel (right). The plans show this is an existing piece of cabinet (the filler) and was not supposed to be disturbed in the 2005 improvements. The cabinet contractor was not doing anything right of that joint, neither was the plumbing contractor, nothing contracted right of the joint in the countertop.

My next observation of importance only hit me after the plaintiffs’ counsel had decided not to depose me. The plumbing party had settled out, the cabinet subcontractor had settled out, this was just plaintiff team verses the tenant improvement GC team. Our counsel Peter Garchi had established the theme that the plaintiff had to directly link the General Contractor to knowledge of the missing plumbing caps. If the actual work being performed by the subcontractor trades persons had done something wrong, missed something or buried something, how could the GC be held accountable if they were unaware of the condition, this was a common-sense approach. Supervision of the sub trades is the responsibility of the General but to what extent? Is the General to look over shoulders as work is being performed? Is the General the onsite babysitter who micro manages all physical hands on work being performed? This was a great theme and was something we could work with, it also fit within what I would be able to testify to as a general contractor expert.

I have testified 3 times in trial when the opposing counsel had decided not to take my testimony in deposition prior to the trial, of those 3 occasions, I have 3 $0.00 defense verdicts. I don’t know why they did not think learning what my opinions were before I spoke directly to the Jury or learning how I was approaching the construction related issues, was important. I was told the plaintiff attorney said something to the effect of, “I don’t need your expert to tell me how to read plans”, ironically during the trial, I did actually educate him on how to read the plans, showing him what he had missed. In every one of those 3 cases, I had my way with the Jury. They had no point of reference, no context, no preview or warning of where we were going or what we were going to say. This is clearly a gift, a wonderful surprise that you do not take for granted.

Keep in mind, I am only talking about the construction elements of this case from my view. There are medical experts that have testified, architectural experts, toxicology experts, laboratory safety standards experts; I am just a little piece of this case. The questions in those instances, to name a few; Are there lasting physical affects from exposure to the noxious fumes? Can human health be affected by the noxious odors that had been described by the plaintiffs’ in this action? What safety standards if any were violated by either the lab workers or the construction personnel? The architects were interpreting the scopes as described in the plans (Construction Documents). This was a complex litigation with many moving parts, several experts, multiple witnesses and of course the plaintiffs claiming the damages.

My last-minute epiphany, just days before I was to testify, came to me maybe a day before Counsel Garchi and I were to sit down and go over my direct line of questioning, sort of lock it down. Of course, it was also just hours before we were to have all of our exhibits to the court. I described the observation and what I had found, first to the associate Attorney Mary Wyman, I also sent photos. She did not get or understand my excitement. I then described it to Peter Garchi, the litigator, he could not understand what I was trying to explain, I went down to their office and showed them. This all ties in with the size of the vinyl floor tile that was visible in my photos at behind the fume hood and what the pattern of the lab floor tile looked like in front of the filler panel in front of the cabinets.

I had noticed through looking at all of the photos that had been deposited, the joint between the filler panel and the new working cabinet box fell directly over a thin ¾” strip of the vinyl floor tile, the pattern of that flooring would be continuous. That thin strip of flooring was to the right side of the cabinet joint from the new working cabinet box to the filler panel. I should mention that this filler panel that nestled up next to the metal fume hood base cabinet was included in the 2001 scope of work when the new fume hood was installed. That little strip of flooring, if the pattern stayed the same in front of the cabinets to the back of the cabinets should have been visible in the photos at the back of the fume hood, but it was not. Just one solid 6”-8” piece is all that was visible at behind this cabinet, it filled between the metal cabinet base and the cabinet end wall where the conduit had been screwed to. What this meant to me was that the filler face panel had a full depth panel running from behind the front face straight back to the back wall. The new cabinet had its own box which came with its own side panel. So, what we are seeing in the back is original and not part of the 2005 construction, this means that the exposed pipe end had never been visible during the 2005 Tenant Improvement. The same cabinet panel we see in the blind photos I took by sticking my camera through the access in the back of the metal cabinet is covering the end of the pipe from being visible. Once I showed counsel my photos and the dimensional, computer generated drawings they understood what I was showing them and the relevance of my finding.

Just because they now understood what I was talking about did not mean they would not give me a bunch of what if’s, playing devil’s advocate, etc. This is where the other side not taking my deposition comes in quite handy. At trial, we started my direct before lunch and finished up just an hour or so after. The beginning of my direct was on background, experience, what I have done on this case, what I relied upon. We did not get to my crucial opinion’s until after lunch, which means plaintiffs’ counsel had no time to fact check anything I was saying, scrutinize my hypothesis or any real rebuttal to the opinions I had formed. They had to begin cross before the end of the day, they did and they finished that same day. I was one of the last to testify in the case, one of the last technical experts the Jury was going to hear.

What they heard from me that day was that the location in the other lab was not part of any contracted work by my client, in fact it was 4’ away from the new contracted work. If you believe the plaintiffs expert about this location, you would have to believe someone took a piece 3-4 feet long, glass pipe, off of the existing drain line and either hid it or through it away because he did not want his company to get paid for the extra work. What they also heard, was this uncapped pipe location behind the fume hood was never even visible because not only had it not been contracted or part of the scope of work of my client but that it was buried behind a cabinet wall that was never removed in the 2005 construction. How could the General contractor be responsible for something he never saw, new existed or within his contracted scope of work?

There is something about connecting with a Jury that cannot be replaced. They can see and hear bullshit when it is in front of them. I don’t try to be cute, or smarmy or defiant, I try and answer the questions like any knowledgeable person in their field would, with confidence, with emphasis when needed. I try and be human, normal, just like them, I explain in a simple way and when you look in their eyes and see they are following what you are saying, nodding with you, you have them. I also always try to use things I see in the courtroom for examples, tangible items right in the room, it often times helps illustrate what you are talking about. Lastly, I don’t care who you are, there are funny things happening all around us, funny things said, word choices that may not be perfectly placed and are humorous. When a jury gets laughing at something you said or your response to an aggressive question, because you were loose and comfortable, they pick up on that, it makes you appear, as I said, human, one of them.

Let me say this, the attorneys I worked with on this case, Peter and Mary, worked miracles in the short time we had to get prepared. I know it came with a lot of long nights, lots of missed lunches and very little sleep the last few days. I have nothing but respect for how it was all pulled together as if they were planning on taking lead in the case from the beginning. The jury came back a few days later, defense verdict $0.00. That was my first trial with Peter Garchi, the next trial we got a defense verdict also. That was the Holtville Bridge, my next entry in a few weeks.